Technical

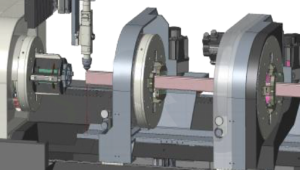

ACCURL® QL.FCT series tube laser offers a full range of material capacities up to 500mm round, with raw material lengths up to 12 meters.

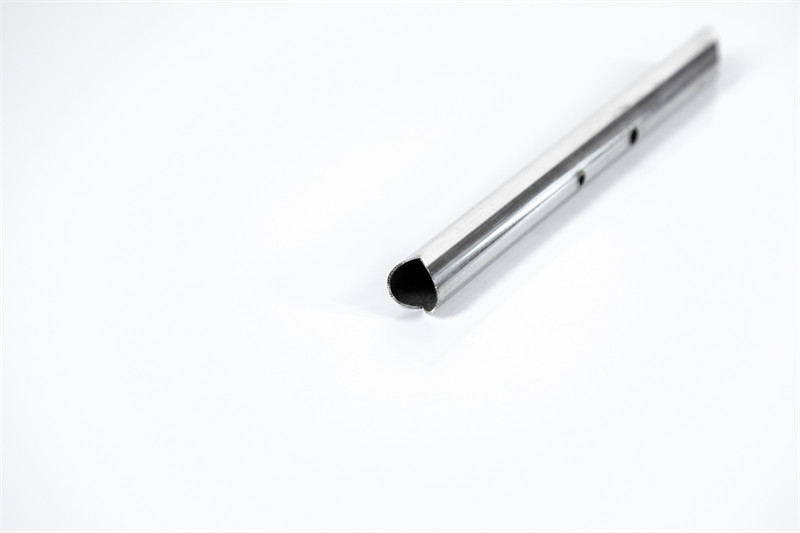

ACCURL® Laser tube cutting is specifically designed for businesses that care about high quality profile & tube cutting. full automatic Loading & Unloading requires less effort and time save for the operator. and Can cut column Crossed Lines at the end of branch pipe, and meet centrifugal and non-centrifugal.

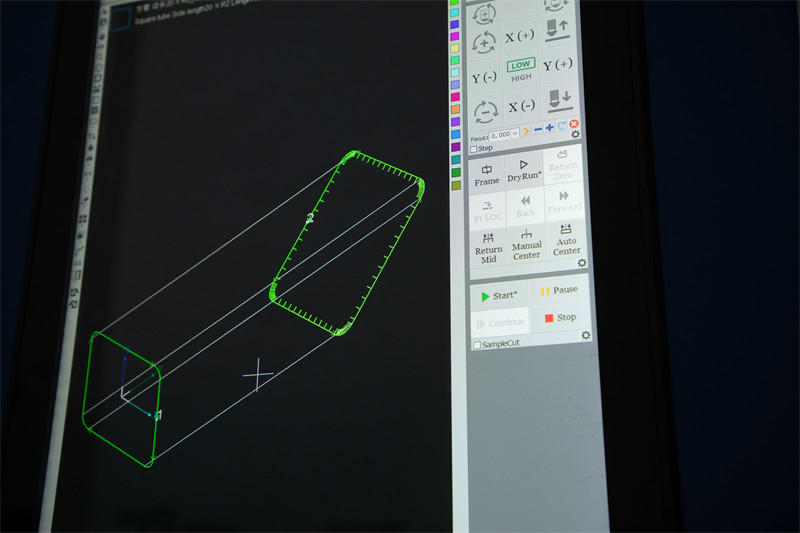

- User friendly FSCUT 5000 TwinCAT CNC control

- Unique features:

- Maximum simultaneous positioning speed: 120m/min.

- Acceleration speed: 13 m/ s2 (1.2G).

- CNC and CAM can calculate complex profiled sections

- Energy efficiency: greatly reduced power consumption.

- IPG Resonator. Power output from 2000W To 6000W

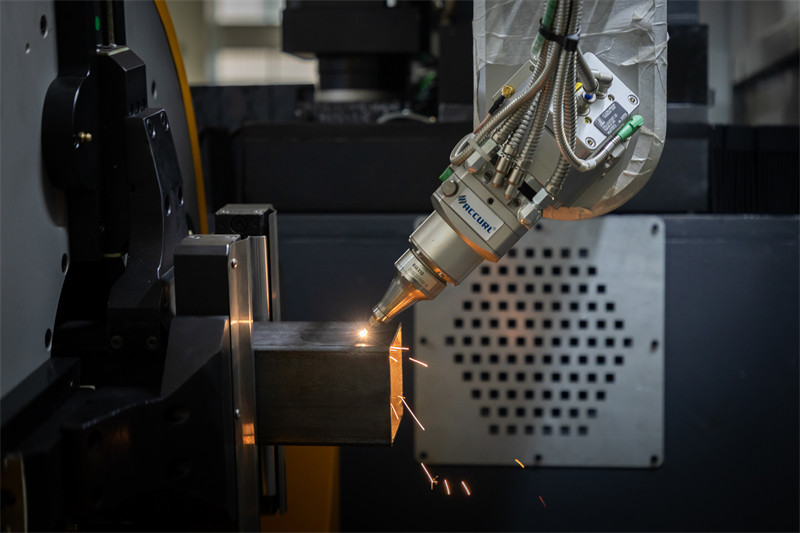

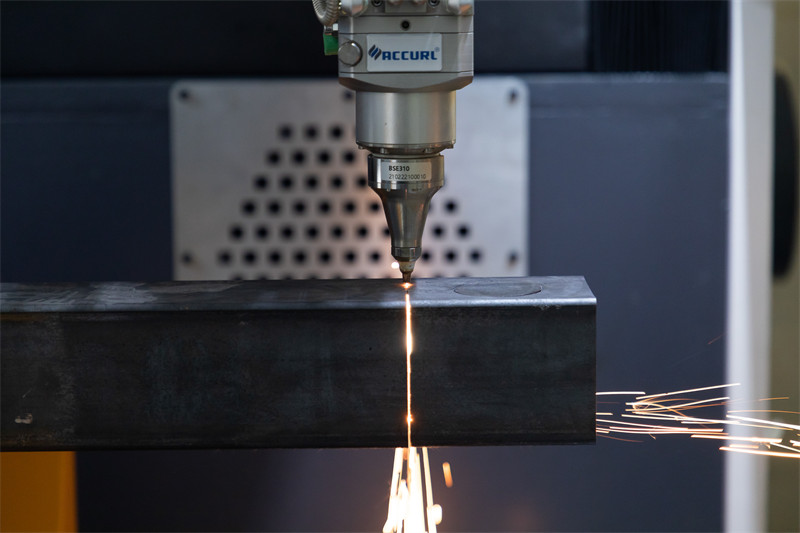

- Advanced Swiss RayTools AG cutting head (with air cross blast).

- φ8-440mm pipe processing range is optional

- The patented technology of three-chuck and zero-tail material high utilization of raw material.

- Effective high to low pressure gas exchange system.

- Automatic time and unit cost calculation function.

- Network connection from external.

- Smoke extraction (included in series models).

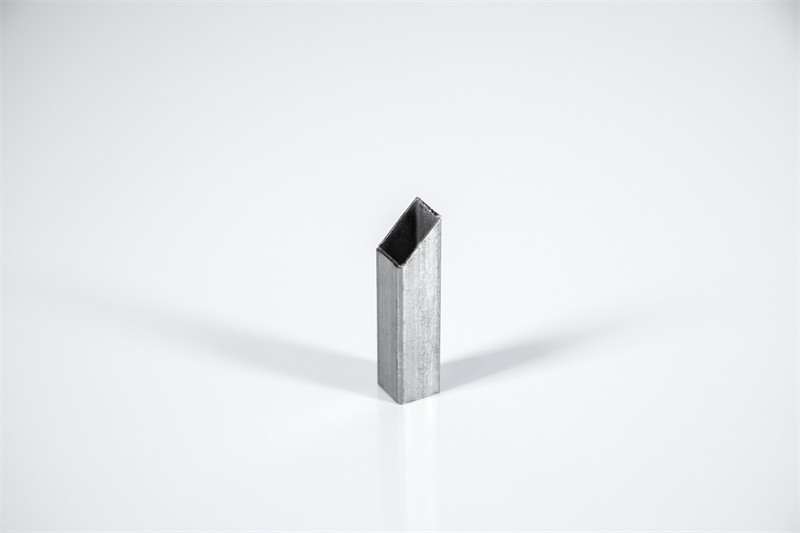

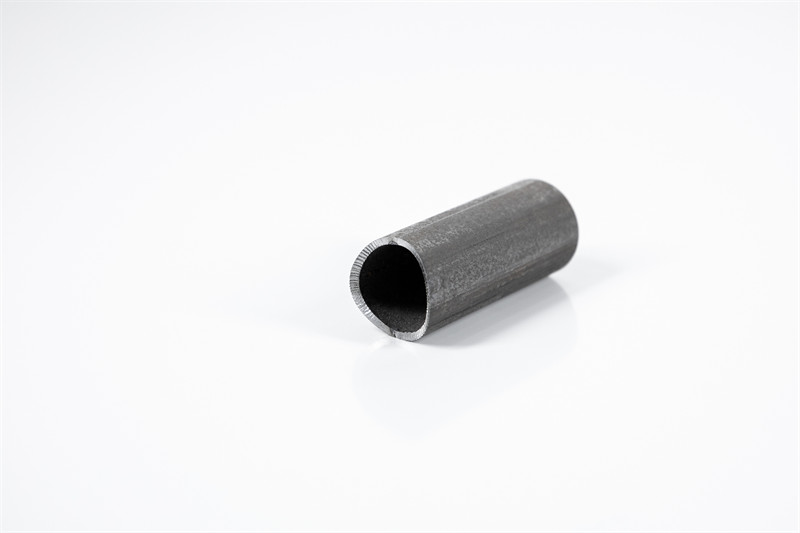

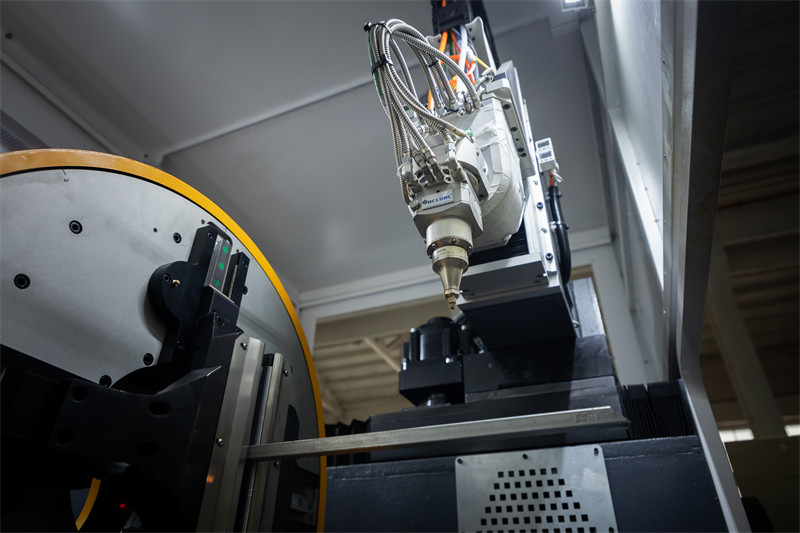

- The “L” shape of the machine assures total flexibility for processing round, square, rectangle “C” / “H” / “I” channel, and angle.

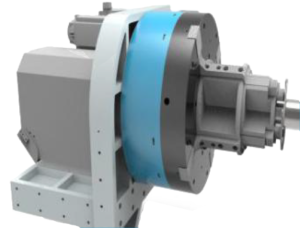

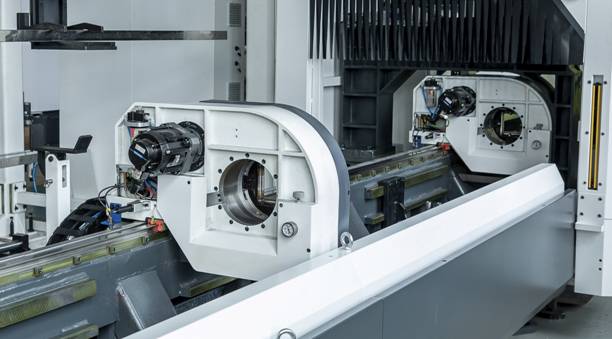

Two high quality rotate chuck move with synchronous rotation, which ensure tube holding more steady . It reduce tube vibration to minimum, with solid guarantee for high accuracy in complicate tube figure. Suitable for cutting tube with diameter range from Ø15mm to Ø320mm

Front Chunks

The X、Y、Z linear Axis and A、B rotary Axis both adopt imported large torque servo motor, high precision, high speed, large torque, large inertia, stable and durable performance, which ensures the high speed and acceleration of the whole machine.

Medium Chunks

The three chuck real-time to maintain the pipe before and after three-point clamping positioning, cutting space-time running speed can achieve max stable cutting, relative cutting efficiency to be high

Rear Chunks

Independent research and development of the chuck with good sealing and motion characteristics, can hold square tube, round tube, elliptical tube, flat tube, triangle tube, I-beam and other materials.

![]()

Application

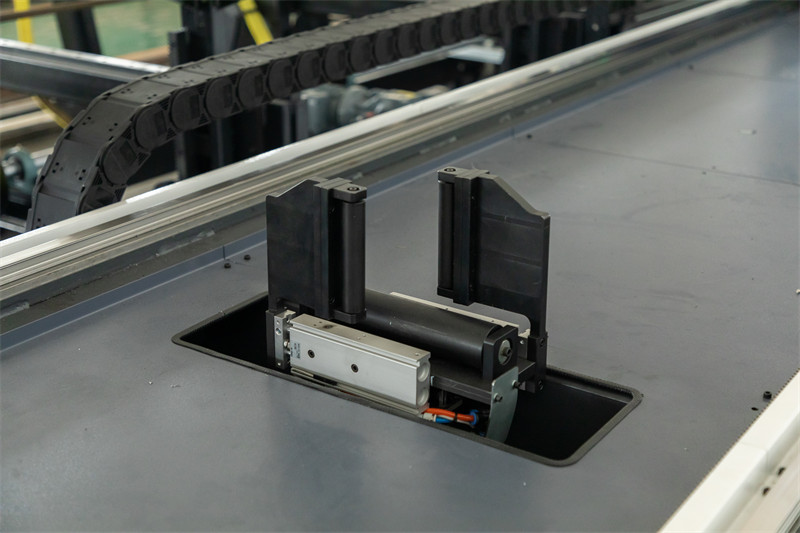

Tube Follow Up Support And Righting Device:

The machine also has tube follow-up support and righting device. Its flat support avoids tube sagging. Follow-up support will lift or fall along with tube rotation to prevent surface friction or scratch. The concave righting device helps to protect tubes from deflection and collision with chucks during loading.

Twin-Chuck Clamping Technology:

For new chuck C2 and C3 are combined as one and can rotate or move synchronously but control its claws opening and closing independently. Except for clamping, tube supporting is also available for the combined chuck, remedying the common weakness of two, three and four chucks.

Cnc Control System:

More specialized in tube cutting based on FSCUT-5000 intelligent system, built-in tube graph database; worry-free production benefiting from automatic generation of processing records and statements; and show 3D special-shaped tube graphs and routes, more intuitive;

Main functions:

•The FSCUT-5000 system of an tube laser control system. because of its outstanding performance in the field of fiber laser cutting, by the vast number of high-end users.

•Equipped with cutting process parameters database, cutting parameters can be adjusted in real time during cutting to achieve the best cutting quality.

FSCUT 5000A CNC System Features:

•22” high resolution colour TFT with remote diagnostic function

•pipe surface height tracking control (servo function)

•Back function

•breakpoint return function

•Automatic Edge Search

•Calibrate the central function of the

•pipe in all directions

•High Speed Laser Pulse Function

•automatic calibration

•fast cutting mode, standard cutting function, film cutting, swing cutting, fixed height cutting etc.

•direct perforation, progressive perforation, multistage perforation, blasting perforation, fine perforation, three-stage

perforation, etc.

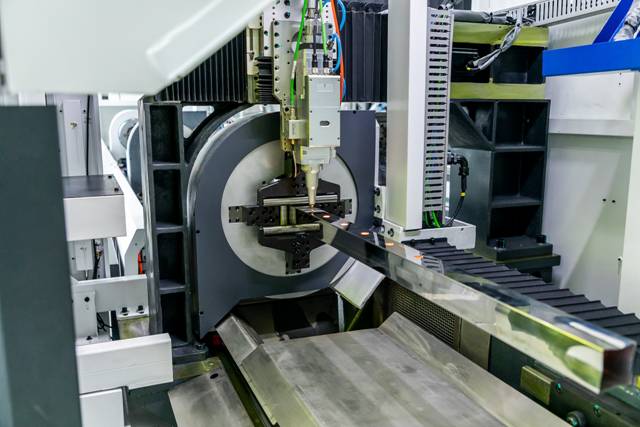

Cutting Head Raytools:

The RAYTOOLS AG comes with the external motor and the built-in drive unit through the linear driver and the focusing lens can automatically change the position in the range of 25mm. The user can set the focus continuously through the program to complete the rapid perpiercing of thick sheets or other different thickness and material sheets.

The new generation impresses with its increased performance and new automation features. Faster, easier, more efficient, more enduring – this is how laser cutting is shaping upin the new generation, due to numerous developments.

As main characteristics:

- Motorized focus position adjustment

- Lightweight and slim design created for fast acceleration and cutting speed

- Drift-free, fast-reacting distance measurement

- Permanent protective window monitoring

- Automated piercing

- Water cooling of the sheet metal with CoolTec

- Completely dustproof beam path with protective windows

- LED operating status display

- Anticollision system included

- Drawer-type of lens mount, quick and easy access to the cover glass

- Pressure monitoring in the nozzle area (gas cutting) and in the head

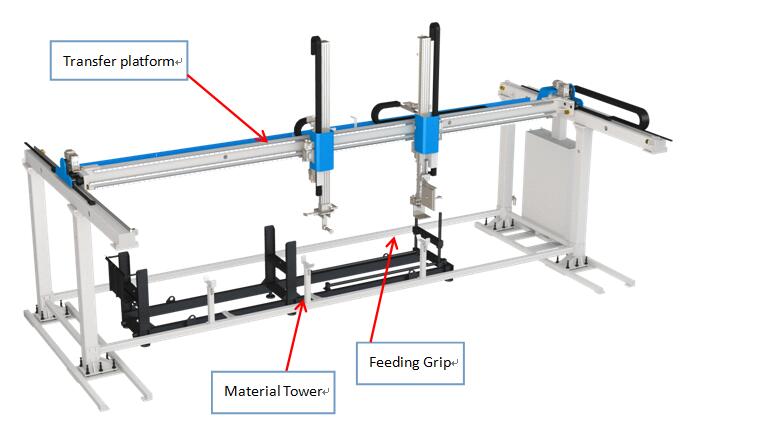

Automatic Mechanical Loading System Atl-60:

Height Limit module:

Automatically distinguish the long and short sides of the rectangular tube to ensure that each rectangular tube is laid flat and forward.

Material frame module:

The whole bundle of pipes is hoisted and loaded into the material frame.

Length measuring module:

Flatten the pipe to the length of the pipe and transfer the date to the host.

| Serial No. | Performance type | Parameters |

| 1 | Collocation model | QL.FCT-6020B |

| 2 | Conventional feeding tube type | Round tube, square tube, rectangular tube |

| 3 | Size of feeding | Round tube:φ25-φ180 |

| Square tube: □25-□180 | ||

| Rectangular tube : The short side≥25mm,Long side≤180 | ||

| 4 | Loading of frame | 3000kg |

| 5 | Maximum weight of single | 260KG |

| 6 | loading length | 3500-6000mm |

| 7 | Completion time | 120S (clamping of chuck on first pipe) |

| 8 | Completion time | 20S (chuck clamping on tube) |

Loading Size:

The size range of loading material isφ25-180,square pipe 25-180,can load round pipe, single pipe bearing 260Kgs

and the first loading time is less than of equal to 120s,and the subsequent loading time is less than or equal to 20s.