Product Description

Fiber metal laser cutting machine

1. Low cost and the power consumption is 0.5-1.5kw/h; Customer can cut all kinds of metal sheets by blowing air;

2. High-performance. Imported the original packaged fiber laser, with stable performance and the lifespan is over 100,000 hours;

3. High speed and efficiency, the speed of cutting metal sheets close to tens of meters;

4. The laser maintenance free;

5. The cutting edge looks perfect and the appearance is smooth and beautiful;

6. Imported the transmission mechanism and servo motor, and high cutting accuracy;

7. Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation.

Parameter of Fiber metal laser cutting machine

| Laser Power | 500W | |

| Laser Source | Raycus or IPG Laser Fiber Laser Source | |

| Laser Type | Imported Fiber Laser or Top Brand China Fiber Laser | |

| Laser Technology | Germany Technology | |

| XYZ Working area | 2500*1300 | 3000*1500 |

| Max. Cutting Thickness (CS) | 1mm - 5mm | |

| Max. Cutting Speed | 5-15 Meters / Min (up to materials) | |

| Max. Location speed | 60m/min | |

| Laser wavelength | 1070nm | |

| Minimum line width | ≤0.1mm | |

| Location precision | ≤±0.05mm | |

| Re-location precision | ±0.02mm | |

| Max. moving speed | 100m/min | |

| Supporting Format | PLT, DXF, BMP, AI | |

| Power demand | 380V/50Hz | |

| Cooling Way | Water Cooling | |

| Worktable max. load | 1000KGS | |

| Transmission Method | Ball Screw Transmission | |

| Table-driven system | Japanese Imported Servo Motor & Driving System | |

| Focus Method | Following and Automatic Adjust Focus | |

| Control Method | Offline Movement Control | |

| Control software | Perfect Laser Professional Laser Cutting Software | |

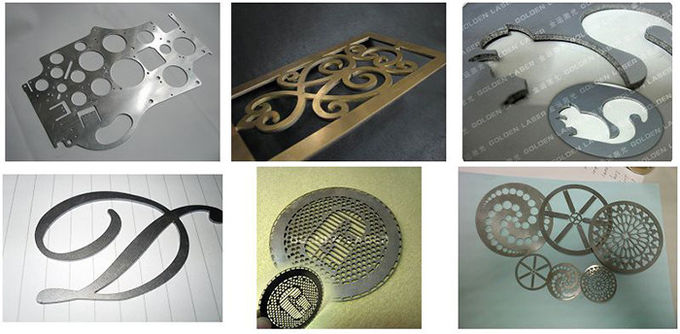

Applcaition and Sample

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile

machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts,

tool processing, adornment, advertising, metal foreign processing various ma

Laser source option

Raycus: 500W, 750W, 1000W, 1500W,2200w,3300W,4400W

IPG: 500W,700W, 1000W, 1500W, 2000W, 3000W, 4000W,

Different laser power due to the different laser cutting thickness,materials and the production quantity.

Installation

After the machine reach the buyer's site,the engineers from the seller are responsible for machine installation

and commissioning by using the special tools under the help of the buyer. Buyer should pay for our engineer

visa fee, air tickets, accommodation, meals etc.

The common protection knowledge of laser safety

The basic principle of laser module and the structure of laser cutting machine

The operation skills of fiber laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Installation & training time is about 5 to 7 days.

Warranty and Service

1). 1 year warranty for the whole machine

2). 2 years warranty for the fiber laser source

3). Life-long maintenance

4).In the warranty period,if it break down or some parts damaged(Except the human factors and the factors

of force majeure),the seller should be responsible for repair for free,the parts need to be replaced will be

provided from seller for free(Except the quick-wear part).

5). After the warranty period expired,the buyer only need to pay the actual maintenance cost.

6).Some customer, we will pay a return visit for several times one year,and will provide technical support

service anytime,and also provide spare parts anytime the buyer want.

7).After sales service response time: quick response within 8 working hours,after receive the repair call,

our after sales engineer will reply as soon as possible.