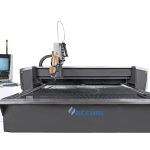

Product Description

Product Application

The Accurl@ Fiber Lasers bring you a cost effective, low-maintenance, low operating cost,environmentally friendly solution to your organization. We deliver a machine that providesquality cutting and tolerances with small productivity loss between jobs, equating to higher returnon investments. Our fiber laser cutting machines are developed and sold based on these criteria.

Accurl@ Fiber Laser Cutting Machine is produced with efficient and ecological fiber laser technology with the proven reliability and flexibility.

Accurl@ Fiber Laser Cutting Machine can be used to cut a wide range of materials. Fiber lasers are more effective than other laser sources for cutting highly reflective materials e.g. aluminium alloys, cooper, brass...etc. Varied thicknesses (up to 22 mm of mild steel) can be cut with efficiency and quality. Productivity increases particularly with thin sheet metal with almost zero maintenance and 70% less cutting cost compared to CO2 lasers.

General Features:

• %70 low electricity consumption in comparison with CO2 Laser

• Up to %300 faster cutting

• High wall plug efficiency (>%30)

• Flexible beam path

• Maintenance free

• Copper, brass cutting ability

• High output power

• High optical quality

• Compact size

• Reliability

Standard Equipments

• IPG Ytterbium Laser Resonator

• Linear Driven X, U and Y Axes

• High Rigid Frame

• 17” LCD Touch Screen Controller

• Precitec Cutting Head

• Lantek Software

• Shuttle Table

• Chiller Unit

• Proportional Gas and Piping System

• Dust Filter

• Compressor

• Conveyor for Scraps

Detailed

Machine body

1.the steady gantry framework provides an open worktable

2.Synchronous X/Y/Z axes: The Z-axis can run 150mm, suitable for cutting many varieties of metal sheets.

3.High quality guarantees its durability and easier maintenance.

Conveyor System

A special hard steel construction conveyor system, standard on our machines, is located under the workspace. The conveyor removes slag and small parts during the cutting process. The operator can choose the movement direction of the conveyor.

HIGH PRECISION DRIVE SYSTEM

The Wittenstein high precision helical gear rack and pinion system uses precision planetary and servo-worm reducers. Our special design eliminates any noticeable backlash variance. The rack used in these systems is also hardened & precision ground.

SINGLE CABLE SERVO MOTOR TECHNOLOGY

1.Accurl has 4 servo motors for all axial movements.These are the latest technology single cable servomotors.

2.Power and process data are transmitted in onestandard motor cable, significantly reducing costs.

3.This technology also gives more accurate positioningand more geometrically accurate parts.

Quick Details

Application: Laser Cutting

Condition: New

Laser Type: Fiber Laser

Applicable Material: Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, plastic, Plexiglax, Plywood, Rubber, Stone, Wood

Cutting Thickness: 40mm

Cutting Area: 1500*3000mm

Cutting Speed: 72m/min

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: cypcut controller

Graphic Format Supported: AI, DST, DWG, DXF, DXP, LAS

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: KJG-150300DT-2000W, KJG-1530DT-2000W

Certification: CE, ISO, SGS, UL

After-sales Service Provided: Engineers available to service machinery overseas

Laser type: USA IPG Fiber YLS-500w

working range: 1500x3000mm

Linear guide: Taiwan HIWIN

Reduction Gears: French MOTOREDUCER

Transmission: Taiwan YYC gear and rack

Laser head: Swiss Raytools auto-following

Table-driven system: Japanese Yaskawa Servo Motor & Driving System

Chiller:S & A for laser source and cutting head

Total Power consumption: Accurl Laser Professional Laser Cutting machine